B2B Prices

Dear valued customers, We wanted to inform you about some upcoming changes to our pricing…

Showing all 6 results

Showing all 6 results

Get a head start on your projects with our handy ideas and inspiration posts, we have created some helpful guides to help you make the right decisions before buy. Stay current with the latest electrical tips on our blog.

Dear valued customers, We wanted to inform you about some upcoming changes to our pricing…

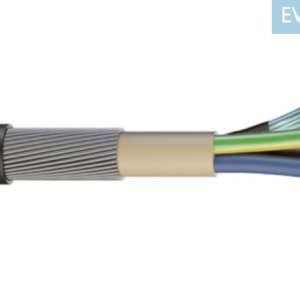

Shop Now EV-Ultra® – 3 Core 6mm SWA or Tuff and CAT5 combined This cable…

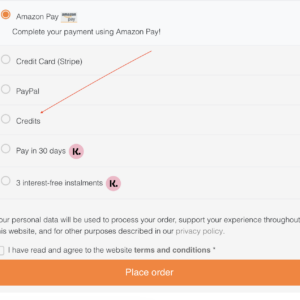

Once your credit account application has been approved you can shop on our website and…

PME Fault Detection Consumer Units also known as PEN Loss Consumer Units in stock now.

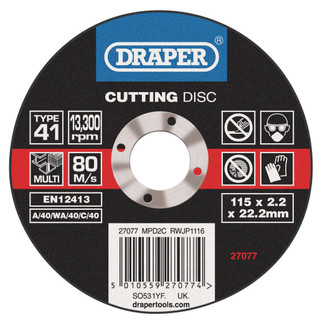

Cutting discs, also known as cutting wheels or abrasive wheels, are commonly used by electricians and other professionals in various trades for cutting materials such as metal, conduit, PVC, and other non-wood substances. While BS 7671 (the 18th Edition of the Wiring Regulations) does not specifically address cutting discs, it is essential for electricians to choose the right type of cutting discs for the job and use them safely. Here are some key considerations for electricians when using cutting discs:

1. Types of Cutting Discs:

2. Disc Diameter: Choose the appropriate disc diameter based on the size of the material to be cut. Smaller discs are suitable for precision cuts, while larger ones are used for cutting larger pieces.

3. Arbor Size: Ensure that the cutting disc’s arbor size (the hole in the center of the disc) matches the arbor size of your angle grinder or cutting tool.

4. Disc Thickness: Thicker discs are more durable and have a longer lifespan but may cut more slowly. Thinner discs provide faster cutting but may wear out more quickly.

5. Material Compatibility: Check the manufacturer’s specifications to confirm that the cutting disc is suitable for the specific material you intend to cut.

6. Safety Considerations:

7. Storage: Store cutting discs in a cool, dry place to prevent moisture or humidity from affecting their performance.

Cutting discs are powerful tools that can make electrical installations more efficient, but they must be used with care and attention to safety to prevent accidents. Electricians should familiarize themselves with the manufacturer’s instructions and best practices for using cutting discs to ensure safe and compliant electrical installations.

To access and complete the B2B client application form, please log in to your account at Electrical4less. If you encounter any issues or need assistance, don't hesitate to contact our support team.