B2B Prices

Dear valued customers, We wanted to inform you about some upcoming changes to our pricing…

Showing all 8 results

Showing all 8 results

Get a head start on your projects with our handy ideas and inspiration posts, we have created some helpful guides to help you make the right decisions before buy. Stay current with the latest electrical tips on our blog.

Dear valued customers, We wanted to inform you about some upcoming changes to our pricing…

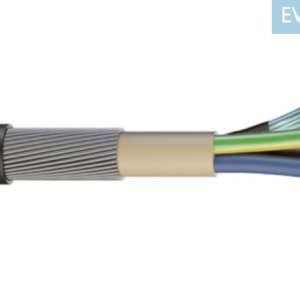

Shop Now EV-Ultra® – 3 Core 6mm SWA or Tuff and CAT5 combined This cable…

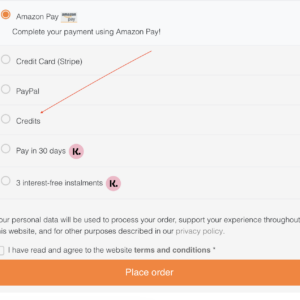

Once your credit account application has been approved you can shop on our website and…

PME Fault Detection Consumer Units also known as PEN Loss Consumer Units in stock now.

Bit holders are essential tools for electricians and other professionals who use power drills or impact drivers in their work. These holders secure various types of screwdriver bits, drill bits, and other attachments, allowing for quick and easy bit changes during tasks such as fastening, drilling, and driving screws. While bit holders themselves are not specifically regulated by BS 7671 (the 18th Edition of the Wiring Regulations), they are valuable tools for electricians to have in their toolkit. Here are some key features and considerations for bit holders used by electricians:

1. Magnetic Bit Holders: Many bit holders come with a built-in magnet that securely holds the bit in place. This magnetic feature helps prevent the bit from falling out during use and simplifies bit changes.

2. Quick-Release Mechanism: Some bit holders have a quick-release mechanism that allows the user to change bits with one hand, providing greater convenience and efficiency.

3. Length: Bit holders come in various lengths to accommodate different types of tasks and working conditions. Longer bit holders are useful for reaching recessed or hard-to-access areas.

4. Compatibility: Ensure that the bit holder is compatible with the types and sizes of bits you commonly use, including Phillips, slotted, square, Torx, and hex bits.

5. Bit Retention: Look for bit holders that securely grip the bits to prevent slippage during use. A secure grip ensures that screws are driven or removed accurately.

6. Durability: Choose bit holders made of high-quality materials that can withstand the demands of daily use in construction and electrical work environments.

7. Ergonomics: Consider the ergonomics of the bit holder’s handle or grip to ensure comfort during extended use.

8. Bit Extension: Some bit holders also provide bit extension capabilities, allowing electricians to reach deeper into conduits or tight spaces.

9. Storage: Bit holders often have a storage feature, such as a built-in bit storage compartment, to keep spare bits readily accessible.

10. Compatibility with Power Tools: Ensure that the bit holder is compatible with your power drill or impact driver’s chuck size and design.

11. Impact-Ready: If you frequently use impact drivers for heavy-duty tasks, look for bit holders labeled as “impact-ready” or “impact-rated” for added durability.

12. Brand and Quality: Consider reputable brands known for producing high-quality bit holders to ensure reliability and longevity.

Bit holders are versatile tools that save time and effort by allowing quick bit changes, reducing the need to search for and manually swap out bits. They are particularly valuable when electricians are working on electrical panels, junction boxes, conduit installation, and various fastening tasks during electrical installations and maintenance.

To access and complete the B2B client application form, please log in to your account at Electrical4less. If you encounter any issues or need assistance, don't hesitate to contact our support team.