B2B Prices

Dear valued customers, We wanted to inform you about some upcoming changes to our pricing…

Showing all 4 results

Showing all 4 results

Get a head start on your projects with our handy ideas and inspiration posts, we have created some helpful guides to help you make the right decisions before buy. Stay current with the latest electrical tips on our blog.

Dear valued customers, We wanted to inform you about some upcoming changes to our pricing…

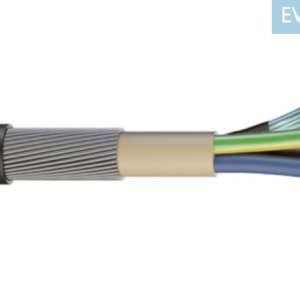

Shop Now EV-Ultra® – 3 Core 6mm SWA or Tuff and CAT5 combined This cable…

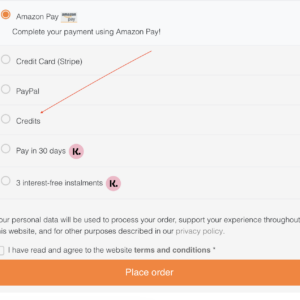

Once your credit account application has been approved you can shop on our website and…

PME Fault Detection Consumer Units also known as PEN Loss Consumer Units in stock now.

Burial grade heavy-duty conduit is an essential component in underground electrical works. It is essential to use the correct burial grade heavy-duty conduit for underground works in compliance with the 18th edition of BS7671. The 18th edition of BS7671 is the British standard for electrical installations, covering design, installation, and maintenance of electrical systems. It is crucial to ensure that the correct grade of conduit is used in underground works to ensure the safety and reliability of the electrical infrastructure.

Burial grade heavy-duty conduit is designed for use in underground applications, where it is exposed to harsh environmental conditions such as moisture, soil acidity, pressure, and temperature changes. The heavy-duty grade of the conduit offers high resistance to chemical and environmental factors, making it ideal for use in underground works. It also features superior impact and crush resistance, which ensures that it can withstand external pressures. Additionally, it is designed with a UV-resistant material that inhibits the breakdown of the material over time due to UV deteriorations.

The correct use of burial grade heavy-duty conduit in underground works ensures the safety of electrical systems. The use of inappropriate conduit increases the risk of electrical faults such as short circuits, electrocution accidents, and electrical fires. The heavy-duty grade of the conduit provides excellent mechanical strength which ensures that there are no breakages that could lead to a fault in the electrical system. The use of inferior conduit could lead to water ingress, corrosion, and the degradation of the insulation material, resulting in the failure of electrical systems.

The 18th edition of BS7671 sets out the standards and guidelines for electrical installations that ensure compliance with health and safety regulations. It specifies the materials, components, and methods of installation that are appropriate for different applications. It is essential to use the correct burial grade heavy-duty conduit in compliance with the 18th edition of BS7671 to ensure that the electrical infrastructure meets the safety requirements set out in the regulations.

In conclusion, the use of the correct heavy-duty grade conduit in underground works is of utmost importance. It ensures the safety and reliability of electrical installations, preventing electrical faults that could lead to accidents such as electrocution and electrical fires. Compliance with the 18th edition of BS7671 ensures that the electrical infrastructure meets the safety standards, providing peace of mind to both electrical contractors and end-users. Therefore, it is imperative to use the correct burial grade heavy-duty conduit in compliance with the 18th edition of BS7671 for underground works.

To access and complete the B2B client application form, please log in to your account at Electrical4less. If you encounter any issues or need assistance, don't hesitate to contact our support team.