Table of contents

1. Introduction to Hager Three Phase Boards

In commercial and industrial power distribution, Hager Three Phase Boards provide the stability and reliability required for high-demand electrical environments. These boards offer efficient and balanced three-phase power distribution, meeting specific requirements for complex electrical systems, and are trusted in sectors ranging from manufacturing to office complexes.

2. What is a Three Phase Board?

Understanding Three-Phase Power

Three-phase power distribution uses three alternating current (AC) waves offset by 120 degrees, providing more efficient and continuous power flow than single-phase power. This setup makes three-phase systems ideal for high-demand environments like factories, offices, and data centers.

3. Why Choose Hager Three Phase Boards?

Hager Three Phase Boards are known for their quality and adherence to UK standards, making them a preferred choice for various applications. Here are some key benefits:

- High Durability: Built with top-quality materials to handle heavy loads and high-demand use.

- Safety Compliance: Hager boards meet UK standards like BS EN 61439-2, ensuring safety.

- Customizable Options: Available in different configurations to suit specific application needs.

- Enhanced Safety Features: Designed with features to prevent electrical faults and enhance protection.

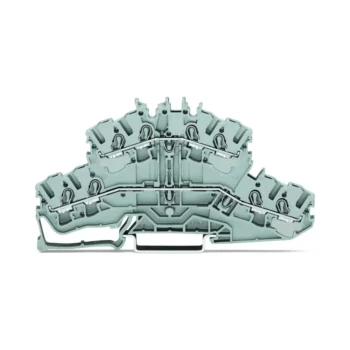

- Ease of Installation: Modular design with accessible wiring, making installation and maintenance easier.

4. Different Types

Available Options

- Standard Three Phase Boards: Ideal for moderate loads, commonly used in smaller commercial installations.

- High-Integrity Boards: Include advanced safety features for critical infrastructure setups.

- Split Load Boards: Allow separate control over different sections of an installation, often used in multi-zone buildings.

5. Applications of Hager Three Phase Boards

Common Use Cases

- Industrial: Reliable power distribution for factories and heavy machinery.

- Commercial: Ideal for large buildings with complex power requirements.

- Renewable Energy: Supports balanced distribution of generated energy in solar or wind setups.

6. Installing a Hager Three Phase Board

Installation Process

Installing a three-phase board involves preparation, mounting, wiring, testing, and ensuring compliance with UK regulations. Hager boards are designed for straightforward installation with modular components and clear labels, simplifying the process.

7. UK Regulations and Standards

Key UK Regulations

- BS EN 61439-2: Governs safety and performance for low-voltage distribution boards.

- Electricity at Work Regulations 1989: Mandates safe installation and operation of all electrical systems.

- IET Wiring Regulations (18th Edition): Outlines protective measures like circuit protection and earthing.

8. Maintaining Hager Three Phase Boards

Regular Maintenance

Routine inspections, functional testing, and connection checks are essential to keep the board in optimal condition. Regular maintenance ensures safety and prolongs the board’s lifespan.

9. Conclusion

Hager Three Phase Boards are a critical component for high-demand electrical systems, offering durability, reliability, and safety. With customizable options and compliance with UK regulations, these boards are a trusted solution for a wide range of commercial and industrial applications.

See the full Hager Commercial range here!

Hager Three Phase Board – Complete Guide