The Ultimate Solution for Reliable Electrical Connections

In today’s fast-paced world of electrical installations, ensuring a safe, secure, and efficient connection is paramount. Whether you’re a seasoned electrician, a DIY enthusiast, or managing complex industrial projects, you need connectors that simplify the process while guaranteeing maximum reliability. That’s where Wago Connectors come in.

Known for their innovative design and engineering precision, Wago Connectors have become the go-to solution for professionals worldwide. In this article, we’ll take a deep dive into what makes them a standout in the electrical industry, why they are favored by so many, and how they can transform your electrical installations.

Table of contents

- The Ultimate Solution for Reliable Electrical Connections

- 1. Introduction to Wago Connectors

- 2. Why Wago Connectors are a Game-Changer

- 3. Types of Wago Connectors and Their Applications

- 4. How Wago Connectors Improve Safety

- 5. Ease of Use: The Tool-Free Connection

- 6. Comparison with Traditional Wire Connectors

- 7. Wago’s Commitment to Sustainability

- 8. Key Features that Set Wago Connectors Apart

- 9. Wago Connectors in Residential vs. Commercial Applications

- 10. How to Choose the Right Wago Connector for Your Project

- 11. Installation Best Practices

- 12. Conclusion

- 13. FAQ: Wago Connectors

1. Introduction to Wago Connectors

Wago Connectors have revolutionized the way we handle electrical connections. These compact, easy-to-use connectors are designed to join electrical conductors quickly and securely, offering a tool-free solution for both professionals and DIY users. From home electrical repairs to large industrial systems, Wago provides a reliable and safe connection every time.

But what exactly sets them apart from traditional methods, like wire nuts or screw terminals? And how can they enhance the quality of your installations?

Let’s dive into the key advantages and explore why Wago Connectors should be part of your toolkit.

2. Why Wago Connectors are a Game-Changer

Wago’s focus on innovation has redefined electrical connections. One of their key innovations is their spring pressure technology, which guarantees consistent connection strength over time. With Wago Connectors, you no longer need to worry about loose connections or periodic tightening of screw terminals.

Furthermore, the convenience of a tool-free design has made them a favorite across the board. Instead of fumbling with screwdrivers, these connectors allow you to simply insert the wire and let the spring mechanism lock it into place.

3. Types of Wago Connectors and Their Applications

Wago offers a range of connectors tailored to different electrical needs. Each type is designed for specific applications, making it easier for electricians to choose the right one for their project. Let’s take a closer look at some of their most popular types:

Lever-Nut Connectors

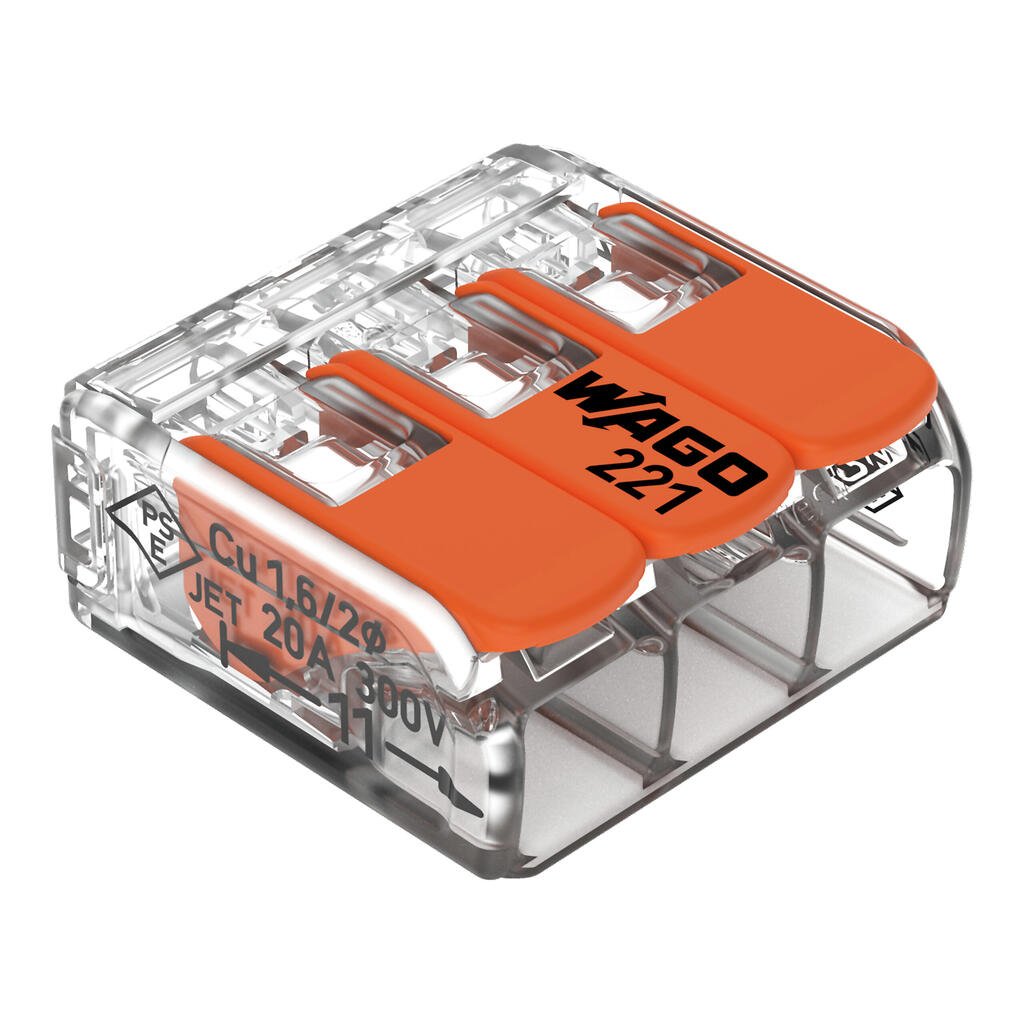

One of Wago’s most popular models, the Lever-Nut Connector, features a lever system that makes connecting and disconnecting wires incredibly easy. Simply lift the lever, insert the wire, and push the lever back down. It’s perfect for quick, temporary, or semi-permanent installations, commonly used in home wiring or during electrical renovations.

Push-Wire Connectors

The Push-Wire Connectors are often used in permanent installations, such as lighting systems or inside junction boxes. You simply push the stripped wire into the connector, and the spring clamp does the rest. This type of connector is ideal for solid or stranded wires and ensures a fast and secure connection.

Spring Clamp Connectors

Spring clamp connectors use Wago’s innovative spring pressure technology to hold the wires securely in place. This method is excellent for industrial and commercial applications, where durability and long-term reliability are critical.

4. How Wago Connectors Improve Safety

One of the main reasons electricians love Wago Connectors is their emphasis on safety. Unlike traditional wire nuts, which can loosen over time, they use spring-loaded mechanisms to maintain constant pressure on the wire. This ensures a secure connection that minimizes the risk of overheating or electrical failure.

Moreover, the connectors are designed to be tamper-proof once installed, reducing the chance of accidental disconnections. In addition, their transparent housing allows electricians to visually inspect the connection, ensuring that everything is correctly in place.

5. Ease of Use: The Tool-Free Connection

The simplicity of Wago Connectors is another significant advantage. These connectors eliminate the need for screwdrivers or other tools, saving valuable time during installation. For many professionals, time saved equals money saved, and Wago’s tool-free design makes it an obvious choice for high-efficiency projects.

6. Comparison with Traditional Wire Connectors

How do Wago Connectors stack up against traditional wire connectors, like wire nuts or screw terminals?

- Time Efficiency: They are faster to install, especially for large projects with many connections.

- Reliability: With traditional wire connectors, there’s always the risk of the wires loosening over time, but Wago’s spring mechanism ensures long-term stability.

- Safety: The consistent connection provided by them reduces the risk of fire hazards caused by loose connections or overheating.

Overall, the time saved during installation, combined with the added reliability, makes Wago Connectors a clear winner over traditional methods.

7. Wago’s Commitment to Sustainability

Wago is not only focused on functionality and safety, but also on sustainability. Their production processes aim to minimize environmental impact. By using high-quality materials and designing products that last, Wago helps reduce the frequency of replacements, which ultimately cuts down on waste.

8. Key Features that Set Wago Connectors Apart

Here’s a summary of the key features that make them a market leader:

- Tool-free installation – no need for screwdrivers or specialized tools.

- Spring pressure technology – ensures a reliable and consistent connection.

- Compact design – fits easily into tight spaces.

- Clear housing – allows for visual inspection of the connection.

- Universal usage – compatible with different types of wires, including solid and stranded.

- High durability – designed to last in both residential and industrial environments.

9. Wago Connectors in Residential vs. Commercial Applications

Wago Connectors are versatile and can be used in both residential and commercial settings. In homes, they simplify common tasks such as lighting installations, outlet replacements, and appliance connections. In commercial or industrial environments, they are prized for their reliability in high-load systems, making them a popular choice in factories, offices, and other large-scale installations.

10. How to Choose the Right Wago Connector for Your Project

Choosing the right Wago Connector depends on the specifics of your project. If you’re working with temporary wiring or need to make frequent adjustments, the Lever-Nut Connector is an excellent choice. For permanent installations, such as home lighting or commercial wiring, the Push-Wire or Spring Clamp Connectors are better suited.

Consider the following:

- Wire type (solid or stranded)

- Load requirements

- Accessibility of the installation site

- Need for future adjustments

11. Installation Best Practices

To ensure optimal performance from your Wago Connectors, follow these simple tips:

- Strip the wire to the recommended length (usually indicated on the connector packaging).

- Ensure the wire is inserted fully into the connector.

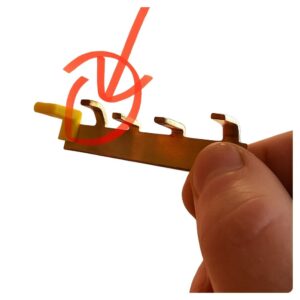

- For Lever-Nut Connectors, make sure the lever is completely locked down after inserting the wire.

- Always perform a visual inspection to confirm the connection is secure and proper.

12. Conclusion

When it comes to modern electrical installations, Wago Connectors stand out for their reliability, ease of use, and safety. They offer a time-saving solution without compromising on the quality of the connection, making them a favorite for professionals and DIY enthusiasts alike. Whether you’re wiring a home, a commercial building, or an industrial facility, they ensure a secure, long-lasting connection every time.

Find all our Wago products in stock here!

13. FAQ: Wago Connectors

Wago Connectors are used to quickly and securely join electrical wires in a wide variety of applications, from residential wiring to complex industrial installations.

Wago Connectors use spring pressure technology to hold wires securely in place. Simply insert the stripped wire, and the spring mechanism creates a firm connection.

Yes, they are designed for both temporary and permanent installations. They meet all necessary safety standards for long-term use.

Yes, they are designed to accommodate both solid and stranded wires.

Absolutely. they comply with international electrical safety standards, including UL and CE certifications.